Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🏗️ Drill Like a Pro, Build Like a Boss!

The BINOTA Concrete Hole Saw features a 115mm tungsten-cobalt alloy tooth design for sharp, efficient cutting, paired with a 220mm SDS MAX arbor compatible with most impact drills. Its cross-type masonry drill bit ensures stable, slip-free operation across various materials including concrete, brick, and cement walls—ideal for professional installations of HVAC, plumbing, and electrical systems.

N**E

Very good core drill set, even better vendor customer service!

I needed a tool for drilling holes in 8" thick poured concrete basement walls for installing a radon system. After searching a number of products and checking reviews, I picked this set as it offered several hole sizes and 2 drive shafts (SDS and SDS Max). I opted to run the 65mm hole cutter based on the size pipe I was running, and wanted to start with smaller hole and only go larger if needed. For the drill motor, I used a HF Bauer 1641E-B SDS rotary hammer.I started the hole using water to flush the dust out of the hole, but this made a sticky sludge that coated the cutting teeth, made a bit of a mess, and slowed down the process. I only ran the drill at about mid speed, so the cutter never got more than a little warm. I cleaned the hole and ran the cutter dry from then on, using a utility vac to keep the debris evacuated. This sped up the process. Overall, it took me about 3 hours to go the 8-9" thru the wall. Again, this was some pretty solid concrete. The cutter never stalled, but it was a slow, steady process. The resulting hole was a little oversize (approx 70cm) but this was reasonable. You will have to stop every so often to chisel out the center concrete as the cutter only cuts the perimeter of the hole. This is the case with any cutter of this depth. The cutter length with the shaft length was plenty to cut the 8-9" thru the concrete wall with a little depth to spare.I had to drill a second location wall hole a few weeks later. As before, I scanned the wall with a metal detector to avoid hitting any rebar. I ran this hole dry, same mid-range RPM, and evacuating with a vac. Only took about 2 hours this time, same wall thickness. After finishing the hole, I inspected the cutter and noticed a couple of the teeth had broken off. Not sure when this happened as the cutter performed consistently and never seemed to slow down. Hole was very clean, no rebar contacted.Since I didn't need a whole new set, I contacted the vendor and explained the nature of the drilling, and asked if I could buy just the 65mm cutter. They very graciously sent me a new cutter and SDS shank (at no charge), which then got lost in shipment. When the vendor found out, they sent another cutter and expedited at their own expense. This is exceptional customer service.Finally, for those considering this set- I used it on a vertical poured concrete basement wall. It is difficult and slow, no matter what cutter you are using. This tool would be faster in hollow cement block, or drilling thru a slab. In any type of poured concrete drilling, do yourself a favor and use a metal detector to avoid hitting any rebar. I am a mechanical engineer and know how to get the most performance from the tools I buy, and I was impressed with this set, even though I knew the job would be a challenge.I'm not easily impressed, but this product and especially the vendor impressed me a great deal. I will definitely buy from them again. My reason for leaving such a detailed review is that it was a struggle finding adequate information about these cutters when I was searching. Finally, this set also includes an SDS Max shank as well as the SDS shank I used. Both are approximately the same length.

B**B

Worked very well

This is the third of this bits on different sizes I buy, always keeping my expectations on check due to some bad experiences shared by other reviewers, but for me they have worked very well. Used this one to make a hole on a concrete wall to pass tubing for a mini split. Following sugestions from other users, I drilled the center hole first. The only thing I could not do was to use water to keep the hole saw cool while drilling because the interior of the wall is plastered and painted so I didn't want to ruin it, and the only way to work was from the inside of the room because reasons. I worked it slow but with enough pressure to feel it was biting the concrete, it took me about 15 minuts to go to the other side of this 7 inch thick wall with the good news the hole saw didn't lose any of the teeth I know other reviewers bits' have lost. So this have being my experience with this not expensive hole saw, tho I still have to see how many times I could use it without it losing some of the cutting pieces, but as for this one time, it helped me to finish this task. I hope this review help some one decide if this is good for them.

S**N

Not bad for $80

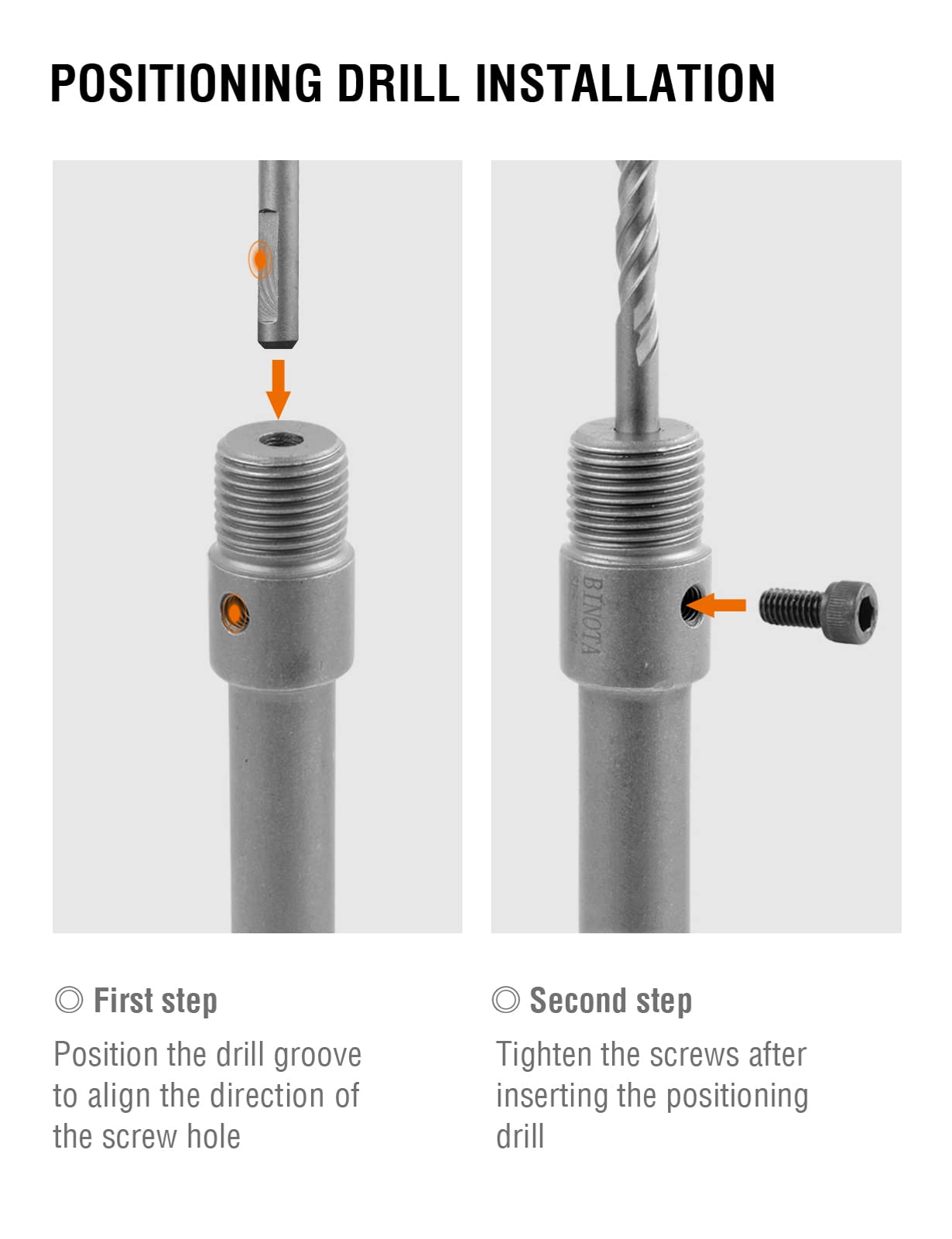

Considering that the "name brands" charge more for a single core saw, this set is not a bad investment. They worked quite well for multiple holes though ancient cured concrete and hollow tile.Drawbacks:1. The pilot bit set screws are plain M6x1 hex head screws, fit loosely and have a tendency to fall out. I replaced them with real M6x1 set screws and teflon tape. One still managed to back out every time.2. Be sure to grease the threads on the mandrels because removing them from the core saws is going to be a task. I needed two large pipe wrenches to separate them.3. The SDS-max mandrel failed within a week. I used a Hilti TE-60-ATC and managed to shear it off as in the pictures. Very disappointing because SDS-plus RP hammers don't have the power to drive the 80mm and 100mm core bits.If anyone knows how to get a replacement SDS-max mandrel, that would be great.

N**R

Definitely worth the $$!

For the $$, i thought this was going to be eaten up after a good use. Nope.Just keep the saw wet and I was real happy. Vs. the Bosch or other masonry bits.Funny idea I had was to out of the blue. I needed to drill a new water line through and old plaster and lath wall in a 1920's house with the real deal tile wall. The mortar bed, wire and tile with plaster and lath.That! Well on a fluke drilling from rough wall opening in to the bath. The saw bullied through and gave me a real clean hole on the tile face.IMPRESSED! WELL MADE made in CHINA.Who cares. Every is made in China.Depending on the level of the corporation that stipulations the product the want and slap a label on it.Meaning = it's all made in China.Name brands don't generally mean crap today anyway.

Trustpilot

2 weeks ago

5 days ago